The Workflow. Tailored to your Role.

Standardized furniture blueprints adapted for Manufacturers, Designers, and Brands.

From Hand Sketch to Visual.

Send us anything — raw hand sketches, .dxf, or SketchUp volumes.

We quickly return a high-quality 3D visualization. This allows you to verify proportions and aesthetics with your client before engineering begins.

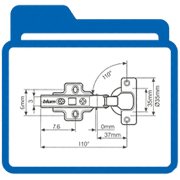

Requirement: Just specify hardware brand (e.g., Blum Legrabox) and material thickness (e.g., Egger H1180 ST37 18mm).

From Visual to Production.

We generate the complete technical package.

Shop Drawings

We configure our software to match YOUR drill bank and nesting strategy. Precise Dimensions Part Naming (e.g. Side_L) Assembly Logic Format: PDF Blueprint

CNC Cutlist

Sawing Sizes (Net/Gross) Drilling Coordinates Machine Compatible Format: Excel / CSV / .MPR / .TCN / .BPP / .HOP / .DXF

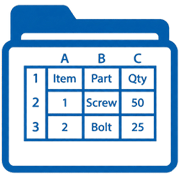

Bill of Materials (BOM)

Board Materials (m²) Edgebanding (meters) Hardware List Format: Purchasing List

What You Receive. Ready to Produce.

Shop Drawings

Precise Dimensions Part Naming (e.g. Side_L) Assembly Logic Format: PDF Blueprint

Machine Code

Native files (.mpr, .xxl, .cix) ready for your specific controller. No manual editing needed.

Bill of Materials (BOM)

Excel/CSV for purchasing. Includes Hardware quantity, Edgebanding metering, and Area m².

We validate your vision before budgeting.

Value Engineering: We review your design for structural integrity and material efficiency BEFORE you send it to tender.

Cost Optimization: Suggesting alternative hardware or construction methods to fit the budget without losing the intended look.

From Concept to Blueprint.

Tender Ready: Professional documentation that allows you to get accurate quotes from multiple joineries.

Approval Process: Clear PDFs for client signature, showing all finishes, joints, and critical dimensions.

We find the right factory for your product.

We select a production partner based on your specific project type (Veneer, Melamine, Solid Wood, or Upholstery) from our vetted network.

Transparent Costing

Low factory prices + our transparent engineering fee. No hidden margins.

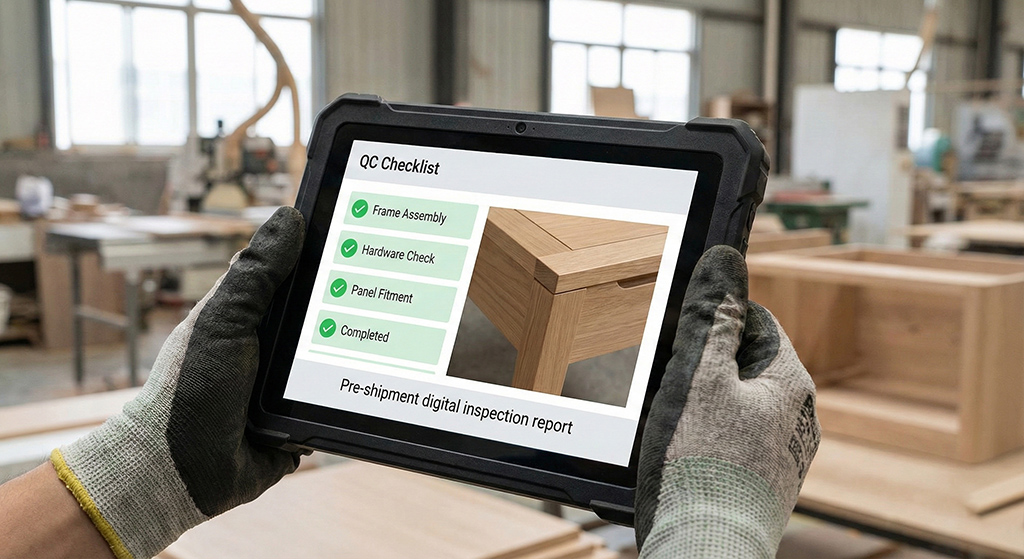

Quality & Logistics

Pre-shipment digital inspection.

You receive detailed photos and a signed QC checklist before shipment.

Blind shipping under your brand.

Goods are shipped directly to your client with YOUR delivery note. The factory remains invisible.

Start with a Pilot Project.

The best way to sync our workflows is to test us on a small unit (e.g., a TV cabinet or a single Wardrobe section).